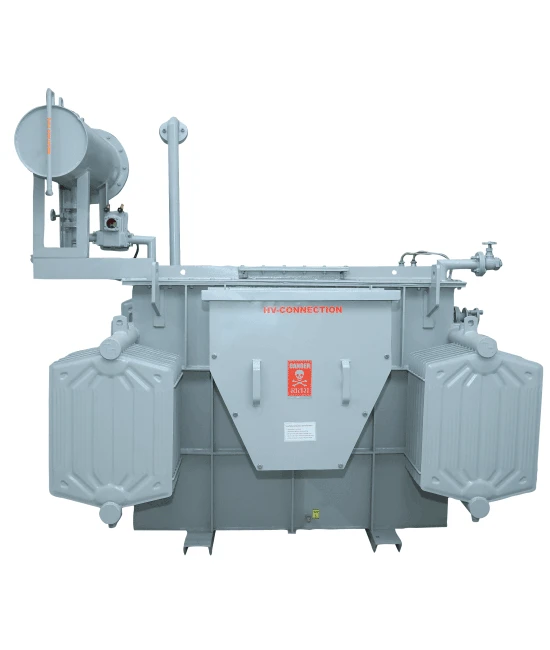

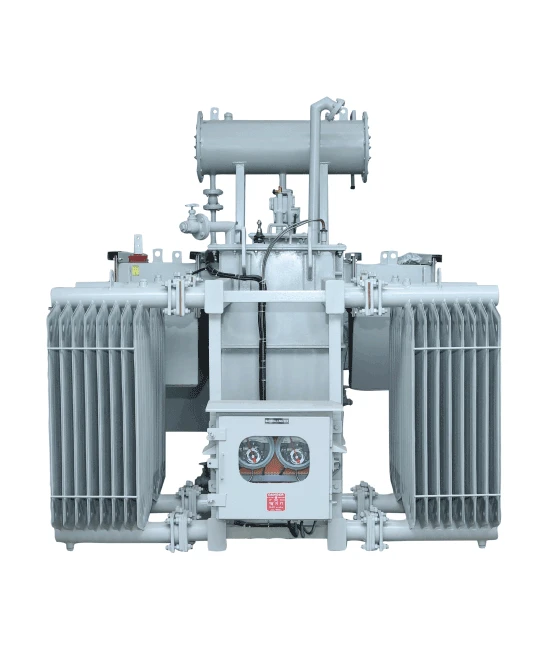

Furnace Duty Transformer

Furnace Duty Transformers: Robust Power Solutions for High-Temperature Application

Our furnace duty transformers are built to withstand the demanding requirements of high-temperature and heavy-duty applications.

Designed for reliability and efficiency, they provide stable voltage and power to arc furnaces, induction furnaces, and other high-heat equipment. These transformers are constructed with durable materials and advanced cooling systems, ensuring they operate seamlessly under intense thermal and electrical stress.

With customizable voltage levels and robust insulation, they meet the specific needs of industrial furnace applications, delivering efficient power with minimal energy loss.

ADVANTAGES :

- High thermal resilience

- Stable voltage output for heavy loads

- Enhanced cooling systems

- Durable, long-lasting design

- Low maintenance requirements

- Customizable voltage and capacity