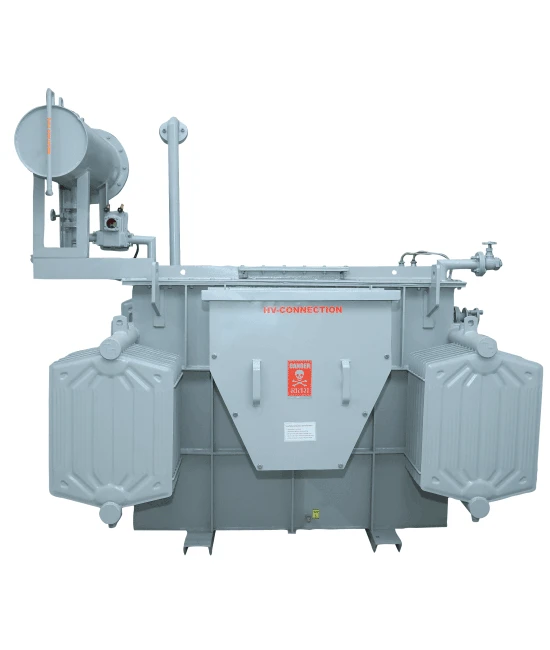

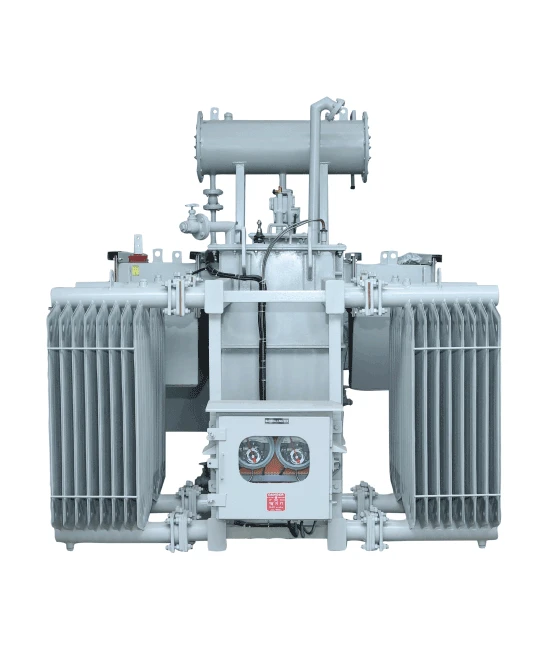

Oltc Transformer

OLTC Transformers: Efficient On-Load Voltage Control for Continuous Power

Our OLTC (On-Load Tap Changer) transformers are engineered to provide seamless voltage regulation without interrupting the power supply.

Designed for high-performance applications, these transformers ensure consistent voltage output even under varying load conditions, making them ideal for industries requiring uninterrupted power. Built with robust materials and advanced cooling systems, they offer long-lasting durability and efficiency.

With customizable configurations and compliance with industry standards, our OLTC transformers are the perfect solution for dynamic voltage control in both industrial and utility sectors.

ADVANTAGES :

- Seamless voltage adjustment during load

- High energy efficiency

- Durable construction for long life

- Advanced cooling systems for better performance

- Customizable for specific applications

- Minimal maintenance requirements